- Being compliant is hard work

- Many business owners & managers are forced to make decisions on what areas of the business receive resources and what don’t.

- Many companies acknowledge the importance of OHS but often don’t have the skills, expertise or time to manage the area sufficiently.

- Custodian Safety Services has the technical capabilities to assist with the management of OHS within organisations.

- Custodian Safety Services provide free company OHS assessments (Gap Analysis), absorb the cost of 1 hour no obligation consultations, have quick job turnaround and guarantee all of our work meets current legislation and standards.

- Custodian Safety Services have assisted companies in multiple industries to date that include commercial construction, rail, telecommunications & waste & recycling.

- Many companies have asked us to continue to develop there OHS systems which is always a good indicator of how successful our work has been.

- We will endeavour to develop the services offered and fee structure based on experiences and we will continue presents the services to companies who we feel would benefit most.

Author Archives: admin

What Nobody Told Me – Hiring an OHS Consultant

Placing your company’s OHS management into the wrong hands can lead to accident’s resulting in injury and/or property damage, inconvenient and avoidable work stoppages and contract delays where clients expect a high level of compliance from contractors. It pays to do your due diligence when choosing an OHS consultancy. Within this article we discuss 4 critical components in choosing the right OHS consultant for your business.

1. Reputation & Quality of Work

Outsourcing your OHS management may have a lot of benefits, but it can also be a significant risk if not put into the right hands. You want an OHS consultancy whom can deliver what’s required with a high level of quality and whom you can trust and establish a long term relationship with. The types of questions you may want to ask include:

- Do they have any solid client references from other similar sized clients like you?

- What success stories can they share?

- What industries do they get majority of their business from?

- What areas do they specialise in?

2. Customer Service & Support

Customer service during the purchase phase is paramount and all good professional service providers will assist in the planning, development, training, trouble shooting, maintenance and upgrading of a service. You should expect to receive a detailed proposal in writing for large jobs or a quotation in writing for smaller jobs. The types of questions that should be answered in the proposal/quotation prior to project completion include:

- Job Delivery Time frame

- Fixed Fee Guarantee

- Professional Indemnity & Insurance

- Confidentiality

- Conflicts of Interest

- Exclusions

- Availability

3. Pricing & Fee Structures

In the OHS consulting services industry it is common place for OHS service providers to charge ‘day rates’ without giving an accurate assessment of how long (or short) a job might be. This ‘open cheque book’ type of fee structure has turned many businesses away from using OHS consultants in the past as they experienced job over runs and often pay far in excess that what was originally forecast. The types of questions you may want to ask include:

- Do you provide a fixed all inclusive job proposal/quotation?

- Can you set and guarantee a job completion date?

- Do you take on jobs under $500 in value?

4. Responsiveness & Dependability

Business moves fast. With that you need to have professional service providers such as accountants, IT and finance brokers to be both responsive and dependable. OHS consulting is no different and you need a provider that can solve your issue or assist your efforts when the time arises in the quality expected from a professional service provider.

Posted by: Cathal Uniacke – cathal@custodiansafety.com.au

What Nobody Told Me – Plant Risk Assessments

Step 1 – Inspect the plant

When identifying hazards, you should think about all the activities that may be carried out during the life of the plant at your workplace, such as installation, commissioning, operation, inspection, maintenance, repair, transport, storage and dismantling. For each of these activities, you should consider whether:

- the plant could cause injury due to entanglement, falling, crushing, trapping, cutting, puncturing, shearing, abrasion or tearing

- the plant could create hazardous conditions due to harmful emissions, fluids or gas under pressure, electricity, noise, radiation, friction, vibration, fire, explosion, moisture, dust, ice, hot or cold parts, and

- the plant could cause injury due to poor ergonomic design—for example, if operator controls are difficult to reach or require high force to operate.

Step 2 – Assess the risks

To assess the risk associated with plant hazards you have identified, you should consider:

What is the potential impact of the hazard?

- How severe could an injury or illness be? For example, lacerations, amputation, serious or fatal crushing injury, burns

- What is the worst possible harm the plant hazard could cause?

- How many people are exposed to the risk?

How likely is the hazard to cause harm?

- Could it happen at any time or would it be a rare event?

- How frequently are workers exposed to the hazard?

Step 3 – Control the risks

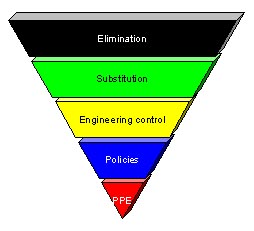

The ways of controlling the risks associated with plant are ranked from the highest level of protection and reliability to the lowest. This ranking is known as the hierarchy of risk control. This may involve a single control measure or a combination of two or more different controls.

Step 4 – Review the risk control measures

You should consult your workers to obtain feedback on the plant and work processes being used and consider the following questions:

- Are the control measures, for example guards, working effectively in both their design and operation?

- Have all hazards associated with the plant been identified?

- Has the purchase of a new item of plant made the job safer?

- Are safety procedures being followed?

- Has an incident occurred in relation to the plant?

- If new legislation or new information becomes available, does it indicate current controls may no longer be the most effective?

This article was taken in part from Safe Work Australia ‘Managing Risks of Plant in the Workplace’ Draft Code of practice we hope you found it informative.

Posted by Cathal Uniacke – cathal@custodiansafety.com.au

Dogman Required?

The debate over whether a dogman is required to sling and lift loads in Australian workplaces has raged on and on countrywide for quite some time now.

Every week you can rest assured that a workplace manager and a client/contractor or employees are at odds about the requirement of a dogman to sling and lift loads.

Unfortunately if we are to consider the issue of dogman requirements across all Australian workplaces and in all Australian states there is no definite yes/no answer to the issue.

If a dogman is needed in ‘every instance of lifting a load’ then every nurse in every hospital and aged care facility should have dogman training which is currently not the case. However, in many construction sites and steel foundry’s dogman training is a pre requisite prior to performing any load slinging/lifting.

Is a bundle of steel being lifted and the persons below any more critical that a patient and a nearby nurse?

To help with this commonly encountered workplace dilemma here are a few notes on Dogman requirements we always use to provide direction:

- If there needs to be an assessment made as to the weight of the load, a dogman is required.

- If there is a need to make a selection of the lifting equipment (sling/chain) needed to lift the object a dogman is required.

- If there is a need to work out where and how the lifting chain/sling is to be attached to the load a dogman is required.

- If the load leaves the sight of the person operating the crane/hoist and whistles or radio signals are used a dogman is required.

The exact requirements on whether a dogman is required or not will continue to vary from state to state based on legislation and industry to industry based on expectations but hopefully you might find these short notes useful.

Posted by Cathal Uniacke – cathal@custodiansafety.com.au

What Nobody Told Me – Site Safety Inspections

Step 1 – Find the Hazards

Start by talking. It’s a legal requirement that safety is discussed in workplaces, and you gain great insights into safety issues and solutions from your workers.

Regularly scheduled meetings, such as tool box talks, production meetings, team meetings are a great way of identifying safety issues.

Make a list of the possible hazards workers are exposed to on site.

Not all injuries are immediately obvious. Some are only discovered over time, such as illnesses caused by long-term exposure to certain chemicals so consider whether these are a hazard in your workplace.

Go through any injury records you have (if you don’t currently have a register of injuries start one now – it’s legally required that you keep one). You’ll be able to see if any problem areas exist, or if any patterns are emerging.

Step 2 – Assess the Risks

After you’ve made your list of possible hazards you need to make a judgment about the seriousness of each hazard, and decide which hazard requires the most urgent attention.

Take a close look at each item on your list. What is the possible outcome if things go wrong?

Are we talking about scratches and bruises, or is there potential for someone to be seriously injured or even killed?

Is it an everyday thing, or something that only comes up now and then, giving you more time to find a solution? Are there things you can do right now, as a short term fix, while you work out a permanent solution?

Once you’ve worked out which hazards have the greatest potential to cause injury or disease, or are a risk to public safety, mark them as your high priority hazards. After that, rank them in priority order from highest to lowest.

Step 3 – Fix the Problems

When you’ve prioritised the hazards on your list, you need to start immediately on the most important step of all – fixing the problems.

Your first aim should be to totally remove the risk. For example, if the risk involves a hazardous chemical, try to find a safe alternative to the chemical. If there is a slipping or tripping hazard in your workplace, see if it can be removed.

If it’s not possible to totally remove a risk, you need to find ways to control it. You might have to alter the way certain jobs are done, change work procedures, or as a last resort provide protective equipment.

You’ll often find there are simple solutions to many of the hazards in your workplace. Most of them will be inexpensive, and some will cost nothing at all. Of course, sometimes there are no straightforward solutions.

There are a number of options you can take in that event:

Check Worksafe publications, alerts and guidance for your industry topics and see if there is a documented solution to the problem.

Talk to other businesses in your industry to see how they handled similar problems.

Seek assistance from the principal contractor on site on how to go about solving the issue (if applicable)

Seek professional advice from consultants or industry associations.

This article was taken in part from the Worksafe Victoria ‘Do Your Own Inspection’ webpage

Posted by Cathal Uniacke – cathal@custodiansafety.com.au

Writing a SWMS

Here’s 6 steps we use when writing Safe Work Method Statements (SWMS).

Here’s 6 steps we use when writing Safe Work Method Statements (SWMS).

1. Title Page

When preparing the title page of a SWMS it is important the following information is available to the reader.

- Work Activity

- Project Name

- Project Address

- Client

- Persons involved in the development & Approval of the SWMS

- Company Name

- Company Address

- Company ABN

- Equipment Used

- Training/Licensing

- Hazardous Substances

- Permits to Work

- High Risk Work

- PPE Required

- Legislation/Standards Referenced when preparing document

2. Risk Matrix

A SWMS should contain a risk matrix that outlines how the hazards will be assessed and rated in terms of consequence and likelihood and what each rating corresponds to in a matric table.

- Step 1. – Identify the credible consequence for each unwanted event

- Step 2. – Determine the likelihood of the event occurring and it resulting in the consequence

- Step 3. – Utilise the risk matrix to identify the risk and risk rating.

3. SWMS Body

The body of the SWMS should be tabular in form and contain the following headings

- Activity Step – 1,2,3,4 etc.

- Activity Process – Job Planning/Induction, Initial Site R.A, Delivery of Materials

- Possible Activity Hazards – Crush injury from plant collisions, Impact injury from falling loads, Electrocution via Overhead Lines etc.

- Initial Risk Score – The corresponding risk score for the hazard, before controls, from the matrix as calculated by the person preparing the SWMS

- Control Measures – What measures are being taken to reduce both the consequence and likelihood of the risk. Control measures should be identified in line with the hierarchy of control. Elimination – Substitution – Engineering – Admin – PPE

- Residual Risk Score – The corresponding risk score for the hazard, after controls, from the matrix as calculated by the person preparing the SWMS

- Control Responsibility – Who has the responsibility of implementing the controls

4. SWMS Work Team Sign On

All employees involved in the works activities must sign onto the SWMS document to acknowledge:

- They have been given the opportunity of SWMS input

- Read and agree with the contents

- Agree to use and work kin accordance with the SWMS

- Will stop immediately if the SWMS cannot be followed

This section is usually tabular in form and with the following headings:

- Employee Name

- Employee Signature

- Date

5. SWMS Amendments Page

A blank SWMS body page with the same headings as the SWMS body above should be available in the rear of the SWMS or at the end of the SWMS initial body to allow for additional/variation work activity SWMS input.

6. SWMS Amendments Work Team Sign On Page

All employees involved in the additional/variation works must review the amended SWMS section and sign on to the SWMS amendment sign on page.

Posted By: Cathal Uniacke – cathal@custodiansafety.com.au

Safety Culture – Where to Next?

In 1993 the UK Health and Safety Commission defined safety culture as:

“The safety culture of an organisation is the product of individual and group values, attitudes,Perceptions, competencies, and patterns of behaviour that determine the commitment to, and the style and proficiency of, an organisation’s health and safety management. Organisations with a positive safety culture are characterised by communications founded on mutual trust, by shared perceptions of the importance of safety and by confidence in the efficacy of preventive measures.”

This definition of Safety Culture has been widely accepted in Australia ever since and was recently cited in the SIA’s Core Body of Knowledge publication in October 2014.

However, the effectiveness of ‘safety culture’ within organisations with regards to the reduction of workplace accidents and injuries has continued to come under the spotlight in recent times.

At an event focusing on OHS I attended recently a university professor at RMIT stated that ‘safety culture is not something that exists or is something that prevents accidents, organisations must work on fixing organisational and management procedures – if they act on this they will fix the problem.’

Another professor, Patrick Hudson has a more positive view on safety culture and in a recent virtual seminar for Safe Work Australia he likens organisational culture to a game of snakes and ladders—we can climb up but also slide down.

He outlines the key components in distinguishing if an organisation has a healthy safety culture is whether it is proactive or reactive with regards to its OHS management and its senior leadership.

He also states that ‘climbing the ladder’ is harder that company’s think but the good news is that his never encountered a companies that wants to go down the ladder and if companies do get up to the top everybody benefits.

Peter’s full virtual seminar can be viewed here on the Safe Work Australia website: http://www.safeworkaustralia.gov.au/sites/swa/australian-strategy/vss/pages/patrick-hudson-culture-ladder

My own opinion as an OHS consultant working day in day out with businesses to improve their OHS Management across all levels is that the development of a safety culture is not a quick fix and is certainly a difficult area to focus our efforts on while still offering justifiable value for money for any business within any industry.

Whatever you opinions are on safety culture and its effectiveness within organisations at the moment this is an area where I will be watching with keen interest in the coming year as the debates surrounding the topic continue.

Posted by: Cathal Uniacke – cathal@custodiansafety.com.au

Current State & Use of SWMS

The Safety Institute of Australia (SIA), with support of RMIT University conducted a seminar on safety in the construction industry. As with last year’s event Safe Work Method Statements (SWMS) dominated the conversation. The frustrations expressed by the crowd were the same as last year – SWMS are demanded for tasks they are not legally required for, they are too big and complex, they are rarely read, they are rarely reviewed and they are written only in English.

It seemed that the audience was waiting for a directive from government on SWMS but the seminar had no speakers from OHS/WHS regulators.

There is little evidence at the moment that SWMS work as intended for non-high risk work although research done recently by Paul Breslin, HSE Manager at Brookfield Multiplex indicates that when SWMS are workable and effective workers like to use them.

The audience also heard how while SWMS are being used for within the construction sector for almost ‘everything’ other sectors with high risk works like manufacturing seem less bound up by SWMS and more on traditional SOP’s for a range of activities. This indicates that the significance of SWMS in construction is high but not a big issue outside of the sector explaining the lack of attention by the regulator.

There has been some voice for moving the current focus of safety in the construction industry away from SWMS and onto the hierarchy of control. This was not discussed at the recent SIA seminar.

Change on the issue of SWMS will only occur when people say no to the demand for SWMS outside their original design and legislative requirement.

The lack of change on the SWMS issue, particularly in Victoria, is a result of everyone waiting for someone else to take the lead on the issue, and no one is. It is possible that Victoria is feeling uncertain, wayward and leaderless given that its Government has chosen to miss the boat on OHS/WHS harmonisation.

Posted By: Cathal Uniacke – cathal@custodiansafety.com.au

SIA’s OHS Body of Knowledge Project

The Safety Institute of Australia has been busy developing a book they call The OHS Body of Knowledge (BOK) in recent years. In early 2015 the final chapters of the book were released.

What is the ‘BOK’

The OHS Body of Knowledge is the collective knowledge that should be shared by Australian generalist OHS professionals to provide a sound basis for understanding the causation and control of work related fatality, injury, disease and ill health (FIDI). This knowledge can be described in terms of its key concepts and language, its core theories and related empirical evidence, and the application of these to facilitate a safe and healthy workplace.

Background

A defined body of knowledge is required as a basis for professional certification and for accreditation of education programs giving entry to a profession. The lack of such a body of knowledge for OHS professionals was identified in reviews of OHS legislation and OHS education in Australia. After a 2009 scoping study, WorkSafe Victoria provided funding to support a national project to develop and implement a core body of knowledge for generalist OHS professionals in Australia.

Audience

The OHS Body of Knowledge provides a basis for accreditation of OHS professional education programs and certification of individual OHS professionals. It provides guidance for OHS educators in course development, and for OHS professionals and professional bodies in developing continuing professional development activities. Also, OHS regulators, employers and recruiters may find it useful for benchmarking OHS professional practice.

Application

Importantly, the OHS Body of Knowledge is neither a textbook nor a curriculum; rather it describes the key concepts, core theories and related evidence that should be shared by Australian generalist OHS professionals. This knowledge will be gained through a combination of education and experience.

Posted By: Cathal Uniacke – cathal@custodiansafety.com.au

This article was taken directly from the OHSBOK website www.ohsbok.org.au

Responsibility of Principal Contractors

Should or shouldn’t principal contractors take responsibility of their sub-contractors?

I have worked professionally in Ireland, USA, UK and Australia and the debate over whether or not principal contractors should take responsibility for their chosen sub-contractors has raged on wherever I went.

I attended a Safety Institute of Australia forum at RMIT university campus in Melbourne at the end of last year where the topic of principal contractor responsibility was on the discussion agenda.

Barry Sherriff, OHS lawyer and partner at Norton Rose Fulbright spoke briefly with regards to principal contractors perceived onus that they must supervise sub-contractors “just because you can supervise doesn’t mean you have too….., you are allowed to rely on that contractor to work safely according to recent court decisions in WA and VIC”

It was apparent to me when listening to Barry and the other guest speakers on the day that the interpretation around whether or not principal contractors are responsible for supervising their sub-contractors has shifted to the side of the principals being allowed to rely on their sub-contractors.

So how do you rely on a sub-contractor? A principal contractor can start by ensuring their chosen sub-contractor can provide:

- Detailed, specific and accurate Safe Work Method Statements for high risk work tasks.

- Ensuring the SWMS are reviewed when substantial changes to work practices occur.

Also, honestly consider questions like:

- Are they up to it?

- Can they develop safe systems of work?

- Can they implement the safe systems of work?

If not the responsibility must be removed from them as if the principal contractor dives in to take charge mid-way through contracts the principle contractor must wear it in the event of things going south.

One thing that can be established is that sub-contractors are going to need to get on board the OHS management train if they want to be considered as serious contenders for standalone work packages in the coming future.

Posted By: Cathal Uniacke – cathal@custodiansafety.com.au